|

Large & Associates

Consulting Engineers |

|

R3238 ASN Authorisation of 1300MWe NPP Steam Generator Tube Plugging Limit

In June 2016 the French nuclear power plant (NPP) operator, Électricité de France (EDF), applied to the nuclear safety regulator Autorité de Sûreté Nucléaire (ASN) for an upward revision in the total number of individual tubes of steam generators (SG) of the 1300MWe series NPPs that could removed from service by plugging. In February 2017, ASN reauthorized the upper limit of plugging be raised from the previously maximum limit of 10% to 18%, this being the second reauthorisation of the plugging limit raised from 5% to 10% in 2013. In addition to allowing a greater number of SG tubes to be plugged, ASN also agreed in May 2017 to permit EDF to repair certain defective tubes by a technique known as sleeving.

This Review analyses the reasoning underpinning this unusually high tube plugging limit and considers the consequences, particularly relating to any performance changes during and in the aftermath of small and large break LOCAs. |

|

R3234 - Operational Nuclear Safety of the Ōma Nuclear Power Plant

Further delays and uncertainties arose because of the upheaval to the Japanese nuclear safety regulatory framework following Fukushima Daiichi events of 2011 and, thereafter, the progressive introduction of the newly formed (September 2012) Nuclear Regulation Authority’s (NRA) Draft New Safety Standards for Nuclear Power Stations (1) and, separately, the Outline New Regulatory Requirements for the Design Basis (2), Severe Accident Measures (3), and Earthquakes and Tsunamis (4) respectively, all introduced in outline or draft form in April 2013. The latest position with the construction programme at Ōma is that ‘safety upgrades’ to suit the NRA’s New Safety and Regulatory Standards and Requirements (items 1, 2, 3 and 4 of paragraph 5) are not planned to commence until 2018 for completion in or about 2023. This project, comprising a number of Expert Evidence Statements to the Court, argues that it is not practical to revise the pre-Fukushima Daiichi design of the Ōma NPP because of its advanced stage of construction and so could never satisfy the New Regulatory Requirements brought about by the Fukushima Daiichi disaster. It is in support of the legal action taken by the City of Hakodate to prevent resumption of construction and the eventual commercial operation of the Ōma NPP in or around 2023. |

|

R3233 - Hinkley Point C - Regulatory Oversight of High Integrity Components

In 2015 the French nuclear safety regulator (ASN) announced that the RPV head components of the FA2 RPV include areas of non-compliance heterogeneity along with the associated drop off in the carbon steel toughness characteristic, thereby rendering the components vulnerable to fast fracture failure. EdF-AREVA submitted to ASN their reasoning that the RPV even with the toughness lowered was fit-for-purpose - part of this demonstration approach included test results from identical RPV top and bottom heads for the now abandoned United States EPR and the UK HPC NPPs. ASN has yet to publish a decision of whether it considers the FA2 RPV fit for purpose but, whatever, both the US and HPC components failed the material tests for toughness. The failed HPC heads were manufactured in advance of confirmation of the HPC order so the question arises whether these critical safety components were subject to UK regulatory oversight via the UK nuclear safety regulator the Office for Nuclear Regulation (ONR) - all the indications to date suggest that no UK regulatory oversight was in place during the manufacture and, not unexpectantly, the French regulatory ASN has stated that it has no role in any aspect of the quality and compliance of the design and manufacture of components destined for overseas NPPs. The regulatory status of the remaining HPC heads is being sought from ONR via a request under the Environmental Information Regulations 2004 although, that said, ONR has been notoriously unreliable in responding to past requests.

|

|

R3238 - Dry-Out Erosion of Fuel Cladding at Leibstadt NPP - Extended Outage

The reason for this extended outage is damage to the nuclear fuel pin cladding, now acknowledged to be due to an in-core phenomenon referred to as ‘dryout’ dating back to the 2012-2013 fuel core cycle. It is now reported that similar levels of fuel pin surface scarring arose in subsequent fuel core cycles. |

|

R3235 - Irregularities and Anomalies relating to Nuclear Reactor Primary Coolant Circuit Components installed in Japanese Nuclear Power Plants

The French are still wrestling with what to do about the 47 potentially flawed steam generator components supplied by the Japan Casting and Forging Company (JCFC), although an immediate measure in the interim has been to somewhat hurriedly shutdown all 12 of the nuclear power plants believed to contained the flawed JCFC SG components, with a decision on the future of these plants awaited from the French nuclear safety regulator Autorité de Sûreté Nucléaire - see LargeAssociates Review R3233. In other words, this composite that has resulted in the French failure includes two elements that are entirely founded in Japan, these being i) that the defective components were wholly manufactured in Japan and ii) that the quality control safeguards that should have prevented the flawed components leaving the place of manufacture failed. The final barrier preventing entry into the nuclear equipment supply chain is iii) the Japanese regulatory system as administered by the NRA - in France this final barrier also failed. |

|

R3233 - Anomalies in the Forged Components of le Creusot Forge

In late 2014, AREVA notified Autorité de Sûreté Nucléaire (ASN) of the results of material tests carried out on a component manufactured at the Creusot Forge. These tests were undertaken by AREVA as part of the much-delayed Qualification Technique of components for the European Pressurised Reactor (EPR) presently under construction at the Flamanville 3 nuclear power plant. The part tested was a supernumerary equivalent of each of the two components, the upper and lower head shells, that had already been incorporated into the FA3 reactor pressure vessel now installed within the nuclear island at the NPP site. |

|

R3229 Tephra Fall-Out and Operational Safety of Sendai Nuclear Power Plants The Review comprises three aspects of the present nuclear safety measures relating to the functioning of the Sendai nuclear power plant (NPP) when subject to high levels of tephra ash fallout from an erupting volcanic event. |

|

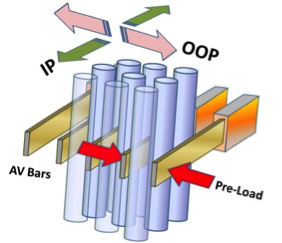

R3218 San Onofre Nuclear Generating Station - Replacement Steam Generator After 25 years of operation, the San Onofre operator, Southern California Edison (SCE), replaced the original steam generators of Units 2 and 3 reactor power plants. Units 2 and 3 are virtually identical pressurized water reactors (PWR) built by Combustion Engineering (CE) and commissioned in 1983 and 1984; each original plant included two steam generators (SGs), both containing about 9,400 thin-walled tubes. |